Alternative Fuels and Raw Materials (AFR) plant refer to waste-derived materials like Solid Recovered Fuel (SRF) and Refuse Derived Fuel (RDF) that are pre-processed and used in co-processing by the cement industry and waste-to-energy plants to reduce CO2 emissions and improve waste management.

Fornnax AFR (SRF/ RDF) plant has a processing capacity of 200 tons to 1000 tons daily. Key features of AFR shredders include high-level safety, environmental attributes with international standards, low maintenance, and impressive efficiency. The plant is auto-controlled by a PLC Panel.

The goal of recycling Municipal Solid Waste (MSW), Commercial & Industrial Waste (C&I Waste), Construction & Demolition Waste (C&D Waste) and Bulky Waste is to produce AFR that can be used as alternative fuel against fossil fuel (majorly Coal) for the Cement industry and Waste-to-Energy plants. It involves shredding and separating heavy particles with metal fractions. Fornnax provides customized solutions to meet customer needs. Fornnax offers a stand-alone AFR Shredder/ SRF Shredder/ RDF Shredder machine and also complete AFR Plant/ SRF Plant/ RDF Plant; the answer will depend on the input material, required output size, capacity and what you need to sort out for recycling.

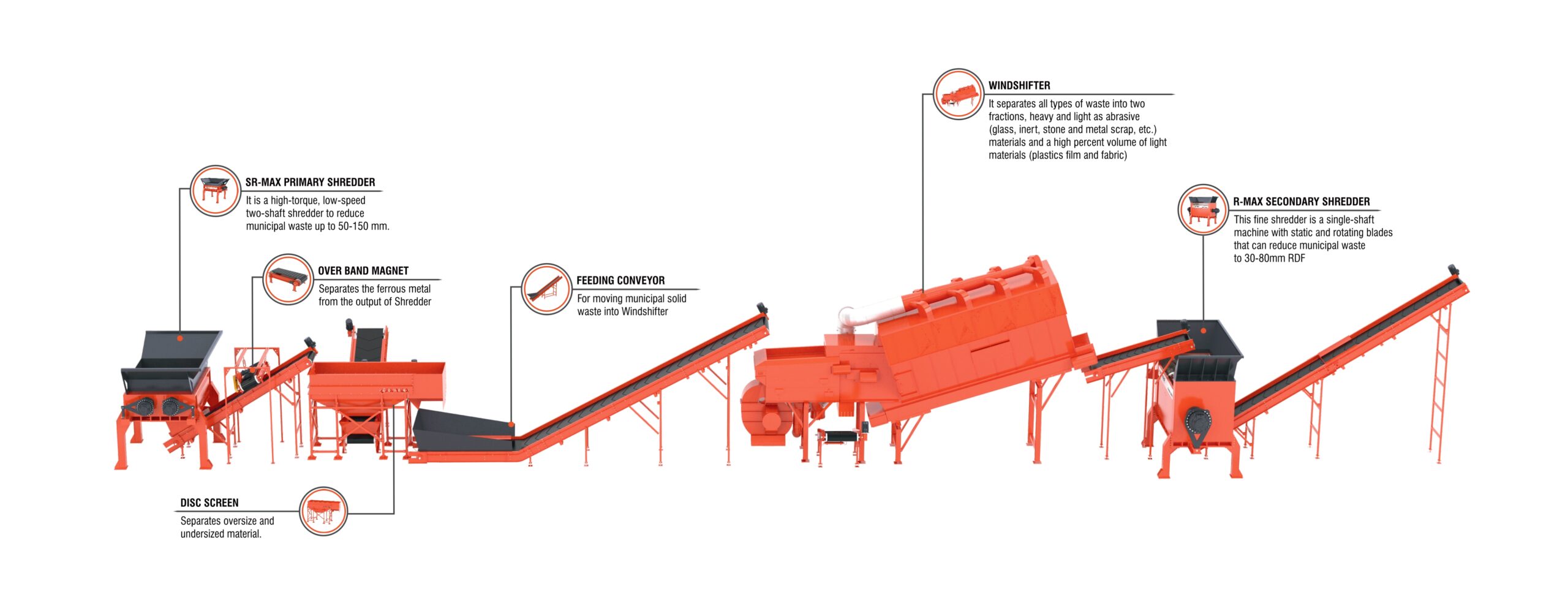

At this stage, municipal and industrial waste is fed into Fornnax SR-Max Series primary shredder through the infeed conveyor system or loader. This unit is a high torque, low-speed equipment, which reduces municipal waste to 50-150 mm variable-size depending on customer requirements. Over-band magnet is available on the discharge conveyor to segregate ferrous metals.

A disc screen is utilized to extract various fractions during this process stage, such as fine particles and oversized fractions, to obtain high-quality, medium-particle SRF/ RDF. The screening technology is selected according to customer requirements.

Windshifter is ideal for separating waste into two fractions, heavy and light. Wind-shifter uses negative pressure technology to sort various materials by density. It separates heavy and abrasive materials such as glass, stone, inert, car scrap, etc. and light materials such as plastic, film and paper, which is high volume in percentage

At this stage, primary shredded mix waste is fed into Fornnax R-Max Series secondary shredder through a conveyor feed system. This unit is heavy-duty medium-speed equipment with a screening system, which produces shred sizes 30 to 80 mm, called RDF/ SRF. The material at this stage can be marketed as high-quality Solid Recovered Fuel/ Refuse Derived Fuel (RDF/ SRF) for various combustion applications.

See how your favourite FORNNAX Plant/Equipment runs.

Videos

Download FORNNAX Brochure now.

Download

Configure your perfect FORNNAX Equipment today.

Configure

Interested in purchasing a FORNNAX Plant/Equipment? Request a quote today for more information.

Request

© 2025 FORNNAX TECHNOLOGY PVT LTD. All rights reserved. | Developed by DreamCode Infotech

Subscribe to the Fornnax newsletter to make sure you get all updates!

At FORNNAX TECHNOLOGY, we prioritize the protection of personal information for all website visitors. This policy outlines our data collection and usage practices, ensuring transparency and security. Read more about our privacy policy. You will receive a confirmation e-mail after subscribing. Click on the link to activate your subscription. You can unsubscribe from this service at any time by clicking the unsubscribe link in the e-mail.