Scrap aluminium consists of contaminated materials such as aluminium sheets, blanks, window frame profiles, mixed profiles, UBC (used beverage cans), aluminium foils, castings, turnings, and rolled aluminium.

Aluminium shredding and recycling aims to produce clean, contamination-free fractions that increase aluminium density. Fornnax scrap aluminium recycling plant includes a broad range of customized shredders and granulators with magnetic separation systems and eddy-current separation systems, which are more efficient, rigid, and consistent. Fornnax aluminium recycling plant generates 98-99% pure aluminium granules free from steel and plastic fractions for further applications.

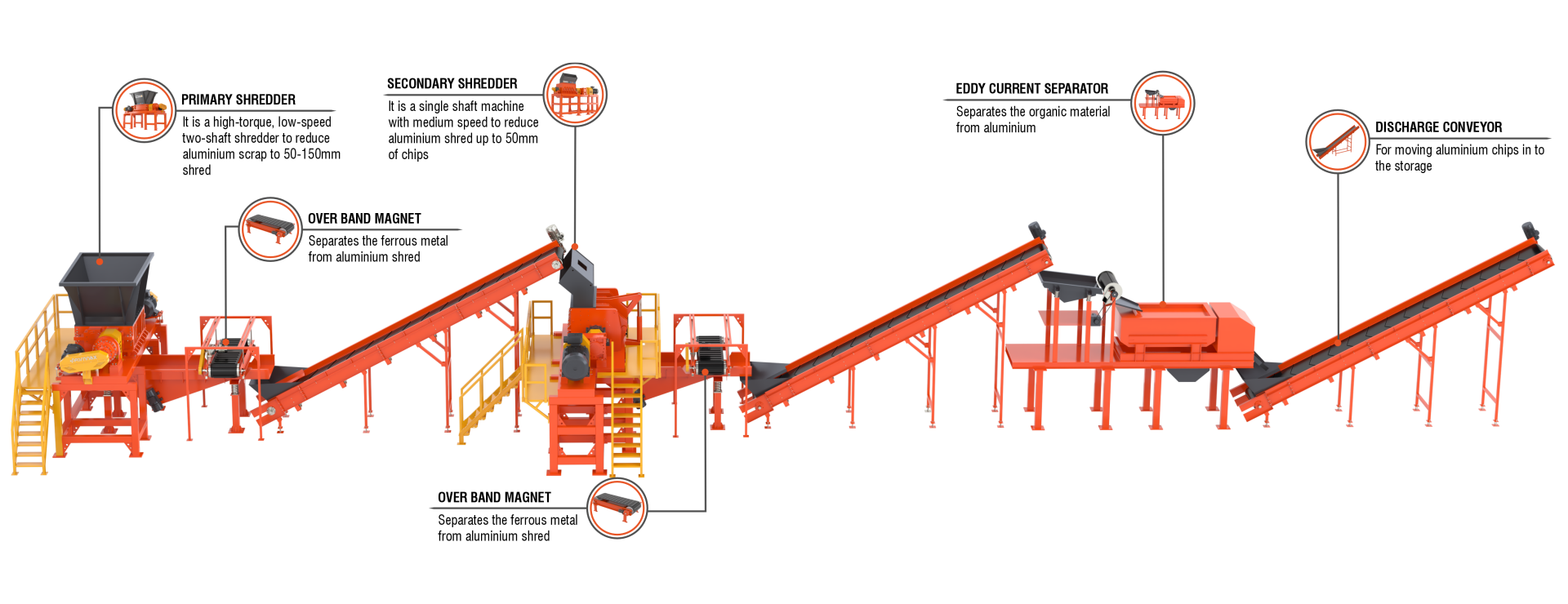

At this stage, bulky aluminium profiles and sheets are fed into the Fornnax SR-Series primary shredder through the loader. This unit is high-torque, low-speed equipment that reduces the aluminium scrap to variable-size shreds. The aluminium shred is approximately 50mm wide x 250mm long, with occasional pieces up to 350mm long.

At this stage, the primary aluminium shred is fed into the Fornnax R-Series secondary shredder through a conveyor feed system. This unit is heavy-duty medium-speed equipment with a screening system, which produces aluminium chips of size 30-50. This process liberates ferrous metal, plastic, wood, and rubber minerals from aluminium chips. OBMS separates Ferrous metals, and the Eddy Current Separator separates other non-metal materials, providing aluminium chips up to 98% steel and contaminants free for further processing. The material at this stage can be marketed as high- quality aluminium chips for further melting and new product manufacturing applications.

The aluminium chip is fed to the Fornnax TR-Series granulator in the granulation stage through the conveyor feed system. TR-Series Granulator is specially designed to accept aluminium chips for further downsizing. This process provides a high-quality aluminium granule with up to 99% purity.

See how your favourite FORNNAX Plant/Equipment runs.

Videos

Download FORNNAX Brochure now.

Download

Configure your perfect FORNNAX Equipment today.

Configure

Interested in purchasing a FORNNAX Plant/Equipment? Request a quote today for more information.

Request

© 2025 FORNNAX TECHNOLOGY PVT LTD. All rights reserved. | Developed by DreamCode Infotech

Subscribe to the Fornnax newsletter to make sure you get all updates!

At FORNNAX TECHNOLOGY, we prioritize the protection of personal information for all website visitors. This policy outlines our data collection and usage practices, ensuring transparency and security. Read more about our privacy policy. You will receive a confirmation e-mail after subscribing. Click on the link to activate your subscription. You can unsubscribe from this service at any time by clicking the unsubscribe link in the e-mail.