INTRODUCTION

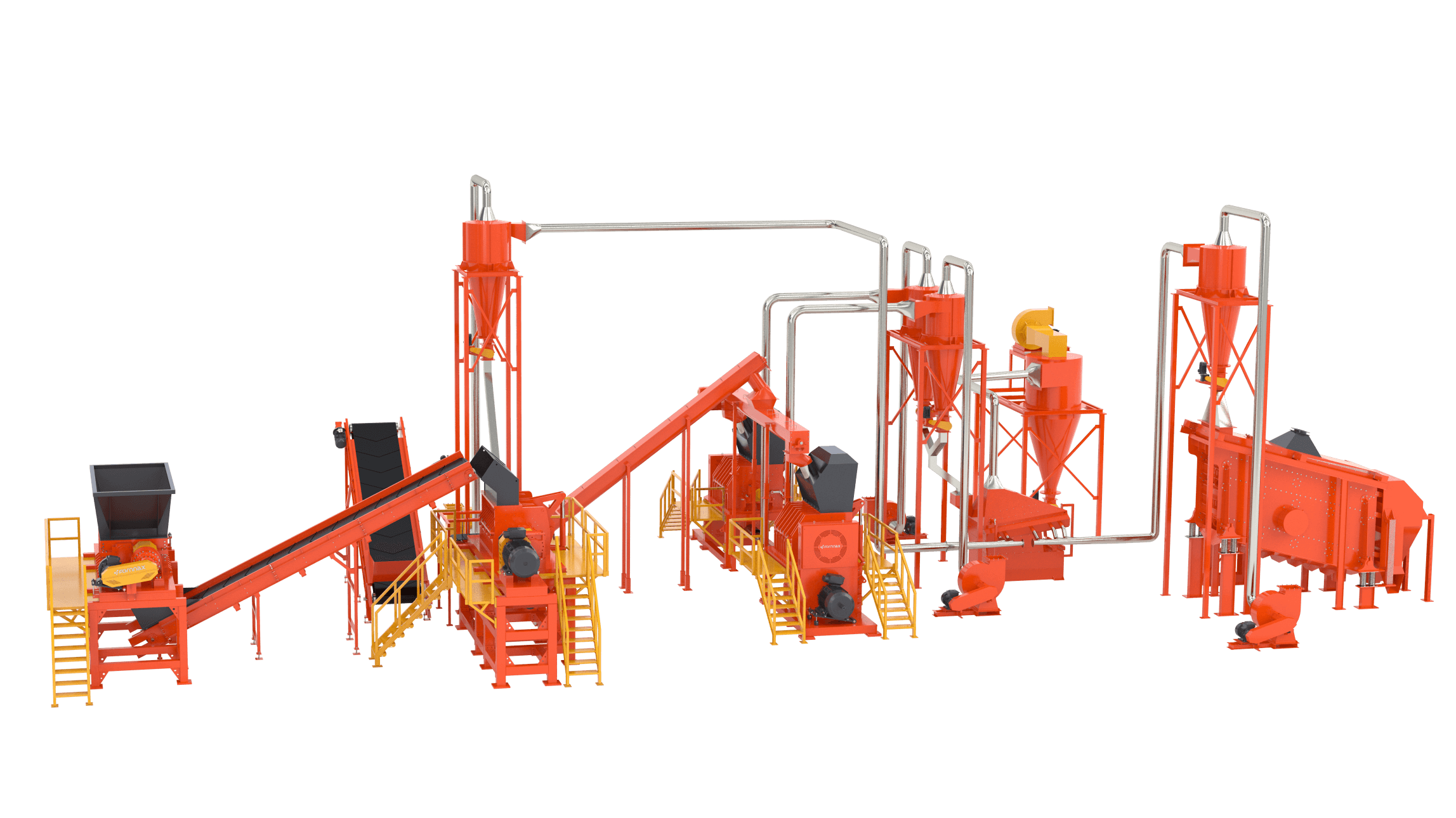

Fornnax introduces world-class design and technology for cable recycling plants with a processing capacity of 25 to 100 tons daily. Key features include: High-level safety and Environmental attributes with international standards. Easy, low maintenance and impressive efficiency. The Plant is auto-controlled by a PLC panel. Fornnax cable recycling plant includes a broad range of customized shredders and granulators, a magnetic separation system, and a separation table with higher efficiency, toughness and consistency. Fornnax cable recycling plant generates 98-99% pure copper and aluminium granules free from steel and plastic fractions for further applications.

PROCESS STAGES

Stage 1: Primary ShreddingIn the primary shredding stage, cable wires will be fed into the sr-series primary shredder, which reduces their size up to 150 mm

Stage 2: Secondary ShreddingAt this stage, the cable wire shred is fed into the Fornnax R-Series secondary shredder through a conveyor feed system. This unit is heavy-duty medium-speed equipment, which produces sizes of up to 20 mm chips, and this process removes almost ferrous material from the shredded cable wire.

Stage 3: Final GranulationIn the granulation stage, the shredded cable chips produced from the secondary shredder will be fed into the Granulator through a conveyor feed system. This unit grinds the shredded cables and produce 1 to 4-mm granules. This process liberates plastic fractions and then separates them through a gravity separation table. The material is then routed through the pneumatic conveying system to the Auto Bag Filling System, which is packed for further applications.

Next Steps

-

WATCH VIDEOSSee how your favourite FORNNAX Plant/Equipment runs.

WATCH VIDEOSSee how your favourite FORNNAX Plant/Equipment runs.

Videos -

DOWNLOAD BROCHUREDownload FORNNAX Brochure now.

DOWNLOAD BROCHUREDownload FORNNAX Brochure now.

Download -

ConfigureConfigure your perfect FORNNAX Equipment today.

ConfigureConfigure your perfect FORNNAX Equipment today.

Configure -

Request a QuoteInterested in purchasing a FORNNAX Plant/Equipment? Request a quote today for more information.Request

Request a QuoteInterested in purchasing a FORNNAX Plant/Equipment? Request a quote today for more information.Request