WATCH VIDEOS

DOWNLOAD BROCHURE

CONFIGURE

REQUEST A QUOTE

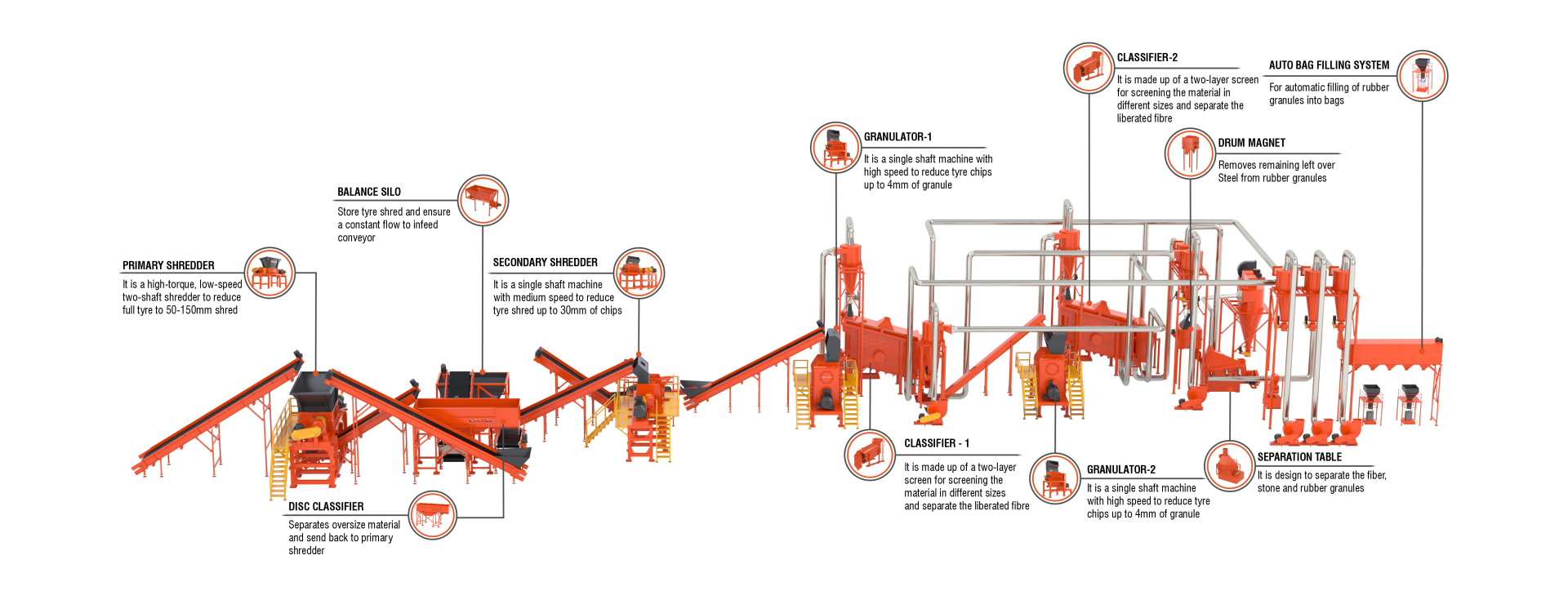

Every tyre recycling facility is unique, depending on the customer’s demands, based on different input materials, such as passenger car tyres, truck tyres, agriculture tyres, and OTR tyres. By choosing Fornnax, you can access decades of expertise in tyre recycling. The result is the highest purity output products, a fully atomized system, and an unmatched level of support before, during, and after the sales.

Fornnax offers all the recycling equipment and machinery you need from one source. It has three stages that produce high-quality crumb rubber granules. It includes customized multipurpose shredders and granulators that produce granules ranging from 0.8 mm to 4 mm.

The tyre is fed into the Fornnax SR-Series primary shredder at this stage through the infeed conveyor system. This unit is high torque low-speed equipment, which reduces the whole tyre to variable-size strips. The shredded tyre strips are approximately 50mm wide x 300mm long, with occasional pieces up to 400mm long. The stripes, sized up to 150mm, are passed through a screening process. Strips larger than 150mm will return to the primary shredder to produce a consistently sized shred averaging 50 mm-150 mm.

At this stage, the primary tyre shred is fed into the Fornnax R-Series secondary shredder through a conveyor feed system. This unit is heavy-duty medium-speed equipment with a screening system, which produces tyre chips of size 20-30 mm called rubber mulch. This process liberates ferrous metal from the bead and tread area and then separates through the over-band magnet, providing rubber mulch up to 98% steel-free for further processing. The material at this stage can be marketed as high-quality, low-steel Tyre Derived Fuel (TDF) for various combustion applications or further granulation.

In the primary granulation stage, 98% of steel-free rubber chips (rubber mulch) are fed to the Fornnax TR-Series granulator through the conveyor feed system. TR-Series Granulator is specially designed to accept steel-free rubber mulch for further downsizing and textile liberation. This process liberates 50% fibre (textile) and then separates through Classifier-1. Material is then routed via a screw conveyor and pneumatic conveying system to the next granulation stage to undergo further reduction or to the Auto Bag Filling System, which is packaged for a broad range of granulate applications.

In the final Granulation stage, primary-granulated material is fed into Fornnax TR-Series granulator through a screw feed system. This unit is high-speed equipment with a screening system, which produces rubber granules of size 0.8-4 mm and separates the remaining liberated 50% textile with the help of classifier-2 and separation table. Secondary magnetic separation removes the remaining leftover 1-2% steel wire. It provides a high-quality rubber granule with a purity of up to 99.9%.

See how your favourite FORNNAX Plant/Equipment runs.

Videos

Download FORNNAX Brochure now.

Download

Configure your perfect FORNNAX Equipment today.

Configure

Interested in purchasing a FORNNAX Plant/Equipment? Request a quote today for more information.

Request